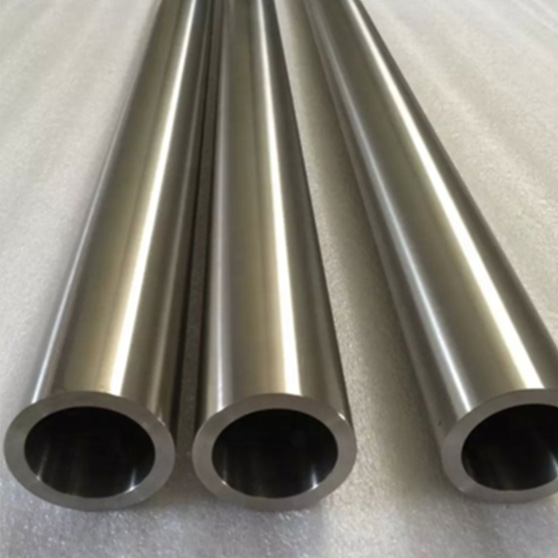

Stainless steel pipe

Seamless pipes and welded pipes represent two different types of stainless steel pipes, which are used in various industrial and commercial buildings, structures, medical and aesthetic applications. Therefore, the choice between seamless pipes and welded pipes depends on the application requirements of the product. Although seamless pipes and welded pipes are common forms of pipe materials, they differ in many aspects. Users should understand these main differences, including the following points:

Manufacturing process

Seamless stainless steel pipes are produced by the extrusion process, which draws solid stainless steel billets into hollow shapes. After heating the blank, it is placed in an elliptical or circular mold, punched in a punching machine, and then stretched in a hot state through mandrels milling technology. The tubes are further formed through Pilger rolling, cold rolling or cold drawing processes. This process can produce a smooth, continuous and uniform surface without weld seams. Seamless tubes are renowned for their uniformity, strength and corrosion resistance, and are suitable for high-pressure and critical applications. The absence of welds eliminates the risk of weak points, making seamless pipes usually stronger, more pressure-resistant and corrosion-resistant.

As the name suggests, welded stainless steel pipes are made by rolling flat stainless steel strips into tubes and then welding the seams to connect the edges. This welding process can form strong and continuous pipes, and the longitudinal weld seam of the pipe extends along its length. Visible seams or weld beads can be selected both inside and outside the pipe, or it can be made smooth by cold rolling and forging methods. Welded pipes can be completed through hot forming and cold forming. Although both hot forming and cold forming can produce durable, strong and corrosion-resistant steel pipes, cold forming can offer a smoother surface and stricter tolerances.

Strength and durability

Of these two processes, seamless pipes are generally regarded as more robust and durable because they do not have the structural weaknesses that weld seams may bring. It is usually the first choice for high-pressure or high-temperature applications. There may be areas with relatively low strength near the weld seams of welded pipes, but the advancement of welding technology has greatly enhanced the durability and quality of welded pipes. Nevertheless, it may not be very suitable for construction projects that require extremely high strength or pressure resistance.

Cost

One of the main advantages of welded pipes is that they are usually more affordable and cost-effective. Seamless pipes are usually more expensive than welded pipes because the production cost is related to the manufacturing time. It involves multiple steps such as heating, forming, machining and milling. The cost of seamless pipes and welded pipes is also related to characteristics such as strength and durability. For instance, the manufacturing process of welded pipes is simpler, allowing for the production of pipes with larger diameters and thinner walls at a lower cost. Seamless pipes are more difficult to achieve these characteristics. Overall, for applications that do not require the extremely high strength and corrosion resistance of seamless pipes, welded pipes are an economical and efficient choice.

Dimensions and supply status

Welded pipes come in a wide variety of sizes, shapes and dimensions, making them more suitable for various applications. In terms of ordering, the delivery time of welded pipes is shorter because their production process is faster and the manufacturing time is shorter. Seamless pipes may have limitations in terms of size and dimensions, which may affect their applicability in certain application fields.

Application

Seamless tubes are an ideal choice for high-pressure and high-temperature applications, such as in the petrochemical, oil and gas, and aerospace industries. It is typically used in applications where corrosion resistance is crucial, such as chemical processing and food production. Welded stainless steel pipes have a wide range of applications, including structural components, automotive exhaust systems, handrails, medical equipment, and many general piping systems.

The choice between seamless stainless steel pipes and welded stainless steel pipes depends on specific application requirements, among which factors such as cost, strength and corrosion resistance are key considerations. The combined effect of multiple factors makes stainless steel pipes an excellent choice for structural applications in industries such as automobiles, aerospace, medical care, and ships. Seamless pipes are typically suitable for high-performance critical applications, while welded pipes are suitable for a wide range of general and cost-sensitive applications.

If you are still unsure which type of pipe is the most suitable for your application, or you have questions about a specific application

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593

#sspipe #seamlesspipe #weldedpipe