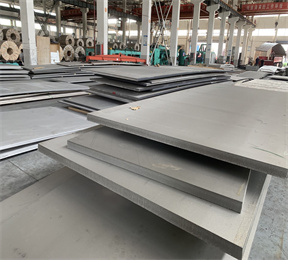

Stainless steel hot-rolled plates are widely used in construction, automotive, machinery, and energy industries due to their excellent corrosion resistance, mechanical strength, and versatility. Understanding the processing methods of these plates is essential for both industrial applications and material selection. Hot rolling is the primary method for producing stainless steel plates, involving several critical stages from raw material preparation to finishing processes.

1. Hot Rolling Process

Hot rolling is a metallurgical process in which stainless steel slabs are heated above their recrystallization temperature, typically around 1100–1250°C, and then passed through a series of rolling mills to achieve the desired thickness and mechanical properties. The high temperature ensures the steel remains ductile, allowing significant deformation without cracking. This process also helps eliminate internal stresses and refine the microstructure, which contributes to improved toughness and formability.

During rolling, the thickness of the plate is gradually reduced, and surface irregularities are corrected. Various types of rolling mills, such as roughing, intermediate, and finishing mills, are employed sequentially. Roughing mills perform the initial large reductions, intermediate mills refine the dimensions, and finishing mills provide the final thickness and surface quality.

2. Annealing and Heat Treatment

After hot rolling, stainless steel plates typically undergo annealing to relieve internal stresses and enhance corrosion resistance. Annealing involves heating the plate to a specific temperature followed by controlled cooling, often in a furnace with protective atmospheres such as nitrogen or hydrogen to prevent oxidation. For certain grades, solution annealing is applied to dissolve carbides and achieve a uniform austenitic structure, which is essential for maintaining high corrosion resistance.

3. Pickling and Surface Treatment

Hot-rolled plates usually develop a scale on the surface due to high-temperature oxidation. To remove this layer and improve surface quality, the plates undergo pickling, which involves immersing them in acid solutions such as nitric and hydrofluoric acid. After pickling, the plates are often passivated to enhance their natural oxide layer, ensuring long-term resistance to corrosion. Additional surface treatments, such as shot blasting or brushing, can also be applied to achieve a specific finish depending on the end-use application.

4. Cutting, Slitting, and Shaping

Once the hot-rolled plates are prepared, they can be cut, slit, or shaped according to customer requirements. Cutting can be performed using shearing, laser, plasma, or waterjet techniques, depending on precision and thickness. Slitting is employed to convert wide plates into narrower strips for further processing. For structural applications, plates may also undergo bending, rolling, or other forming processes to achieve the required dimensions and shapes.

5. Quality Control and Inspection

Throughout the processing stages, stringent quality control measures are implemented to ensure the plates meet mechanical, chemical, and surface specifications. Non-destructive testing methods, including ultrasonic testing, eddy current inspection, and visual inspection, are widely used. Thickness, flatness, and surface roughness are measured meticulously to ensure compliance with international standards such as ASTM, EN, and JIS.

Conclusion

The processing of stainless steel hot-rolled plates is a complex, multi-step procedure that combines metallurgical expertise with precise mechanical operations. From hot rolling and annealing to surface treatment and cutting, each stage plays a vital role in determining the final quality, performance, and durability of the plate. Understanding these processes helps manufacturers, engineers, and end-users select the most suitable stainless steel products for demanding industrial applications.

#StainlessSteel #HotRolledPlates #MetalProcessing #SteelManufacturing #IndustrialSteel #CorrosionResistance #Annealing #Pickling #SurfaceTreatment #CuttingAndShaping #Metallurgy #QualityControl #ASTM #ENStandards #JIS #EngineeringMaterials #IndustrialApplications

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593