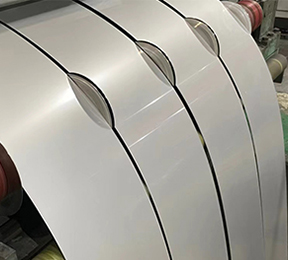

The stainless steel coil segment is undergoing a technological revolution in 2025, with advancements in cold rolling processes elevating product precision and production efficiency. Leading mills across Asia and Europe have adopted advanced tandem cold rolling mills (TCMs) equipped with real-time thickness control systems, enabling the production of stainless steel coils with tolerance levels as tight as ±0.01mm—critical for high-precision applications in electronics and automotive components.

This technological shift is driven by the growing demand for thin-gauge stainless steel coils in the electric vehicle (EV) industry. EV battery casings, heat exchangers, and chassis components require coils with consistent thickness and surface quality to ensure performance and safety. Data from the World Steel Association shows that stainless steel coil usage in EVs increased by 18% in 2024, and this trend is set to continue as global EV production is projected to reach 40 million units by 2030.

Another key development is the rise of continuous annealing and pickling lines (CAPLs) that reduce production time by 30% compared to traditional batch processes. These lines also improve the corrosion resistance of coils by ensuring uniform oxide layer removal, making them ideal for food processing and pharmaceutical applications. “The combination of speed and quality is reshaping the coil market,” notes David Chen, a production engineer at a leading Chinese stainless steel mill. “Our customers now expect faster delivery without compromising on material properties, and these new lines help us meet both demands.”

Regionally, Southeast Asia is emerging as a major consumer of stainless steel coils, driven by its booming manufacturing sector. Imports to countries like Vietnam and Thailand grew by 15% in the first quarter of 2025, as local industries expand their production of home appliances and automotive parts. To cater to this demand, mills are also offering customized coil widths and surface finishes, further enhancing the versatility of stainless steel coils in diverse applications.

Stainless Steel Sheet

Cherry

Website: www.jinyoumetal.com

Email: Cherry@jinyoumetal.com

WhatsApp/WeChat: +86 13373795593

#StainlessSteelCoil #ColdRollingTech #EVManufacturing #PrecisionMetals